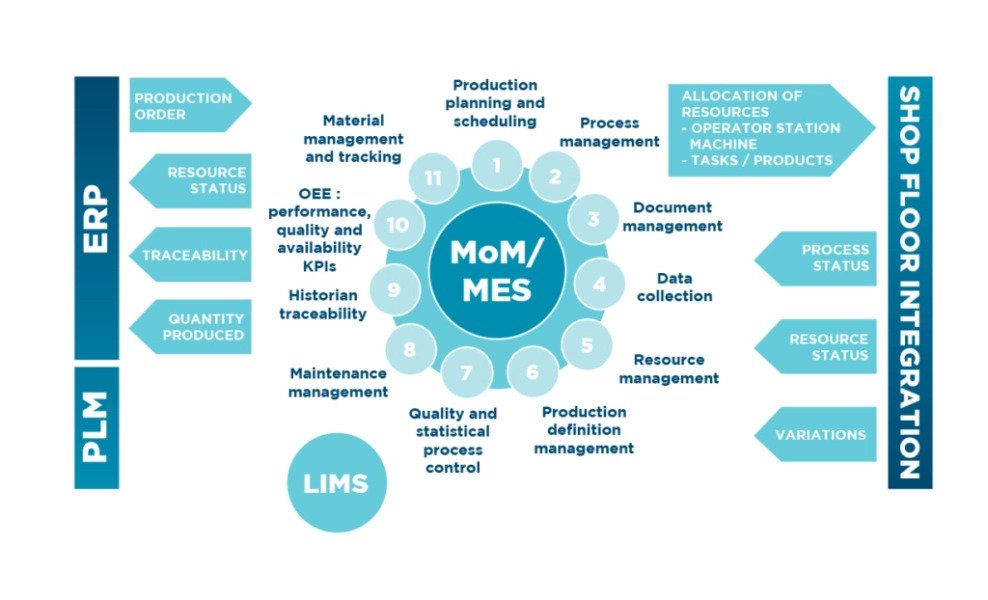

Manufacturing Execution Systems (MES) and Manufacturing Operations Management (MOM) are essential for Smart Digital Transformation. It offers a layer for the self-organized plant’s direct execution of production instructions as well as dynamic reaction to changing conditions in orders, machine statuses, quality checks, and other areas.

MES/MOM are changing the way businesses, goods, and processes are handled. Many firms believe that harnessing the proper technology to improve manufacturing and remain ahead of the curve is the key to staying afloat.

Benefits of MES/MOM The advantages of MES/MOM cannot be emphasized; they have significant influence on a manufacturer's capacity to overhaul and enhance operations. The usual obstacles in manufacturing may be readily handled with an MES. These advantages include, but are not limited to:

1. Production

- Enable full product tracking

- Manage customization and individual orders

- Faster NPI and shorter Product Life Cycles

- Focus on connectivity and data management

- Provide right information at the right time

- Improve efficiency and process visibility with accurate KPI analysis

2. Quality

- Reduce scrap, waste, warranty claims and rework costs

- Record every single defect and enable full traceability

- Eliminate paper checklists

- Support business improvement initiatives to realize right first time

- Improve product quality through flexible SPC analysis

- Reduce cost of critical quality issues

3. Inventory

- Reduce Inventory and Cycle Time

- Avoid risks of missing parts on the line

- Synchronize production flow across different processes and realize effective pull strategies

- Enable dynamic scheduling and sequencing which can adapt to real resource availability

- Streamline the supply chain by interconnecting internal and external suppliers

4. Maintenance

- Schedule the right maintenance operations to reduce costs and impact on production

- Make use of condition-based monitoring for smart maintenance

- Ensure all maintenance engineers are properly trained and keep good records

- Know the real cost of your maintenance operations

You will need MES/MOM if you wish to have more control, compliance, time-to-market, or visibility for controlling product lifecycle execution with correct instructions, real-time data, and manufacturing information.

How DICE Can Help

DICE is one of the world’s leading MES/MOM implementation partners with global delivery capabilities across a broad range of industries. We utilize multi-disciplinary teams and Lean & Six Sigma expertise to design, deliver and support deployments globally across a wide variety of industries. At every stage we focus on the business value that our customers will receive across the four pillars of the ISA-95 model: production, quality, inventory and maintenance.

Does your company need a MES/MOM implementation partner?

Please enter your information below and we will contact you.